Stop Using Chrome! It Hurts People and The Environment

For decades, manufacturers have relied on chrome plating for both decorative and functional purposes. The reflective, mirror-like finish of chrome has long been seen as the gold standard for aesthetic appeal, while its use in industrial settings provided moderate corrosion protection and wear resistance. However, as more is understood about the health risks, environmental hazards, and regulatory scrutiny surrounding chrome finishing, many manufacturers are rethinking their choices. When comparing chrome vs nickel plating, it is increasingly clear that electroless nickel plating offers superior performance, safety, and long-term value.

The Hidden Cost of Chrome Plating: Health, Safety, and Compliance

The most significant drawback of chrome plating lies in the chemistry itself. Hexavalent chromium, the compound used in traditional hard chrome finishing, is highly toxic. Employees who work directly with plating baths face serious health risks, including respiratory disease, skin irritation, and increased cancer risk. These occupational hazards demand extensive safety protocols, driving up operational costs and creating liabilities for manufacturers.

Environmental impact is another major concern. Wastewater generated during the hard chrome plating in Dallas and across the country must be carefully treated before disposal. Improper handling can contaminate groundwater and soil, leading to severe fines and legal consequences. The longer term impact of contaminated groundwater could be catastrophic for a community. As a result, plating operations are tightly regulated by agencies such as OSHA and the EPA, with oversight increasing each year. Meeting compliance standards often requires costly upgrades to facilities, specialized waste treatment systems, and rigorous reporting practices.

Electroless Nickel: A Safer and More Sustainable Alternative

Electroless nickel plating eliminates the toxic risks associated with hexavalent chromium. The process does not rely on hazardous chemicals that pose dangers to workers or the environment. For manufacturers, this translates into safer facilities, simplified compliance, and reduced liability exposure.

But the advantages extend well beyond safety. Electroless nickel coatings deliver exceptional performance benefits that make them more effective than chrome in both industrial and decorative applications.

Superior Corrosion Resistance and Durability

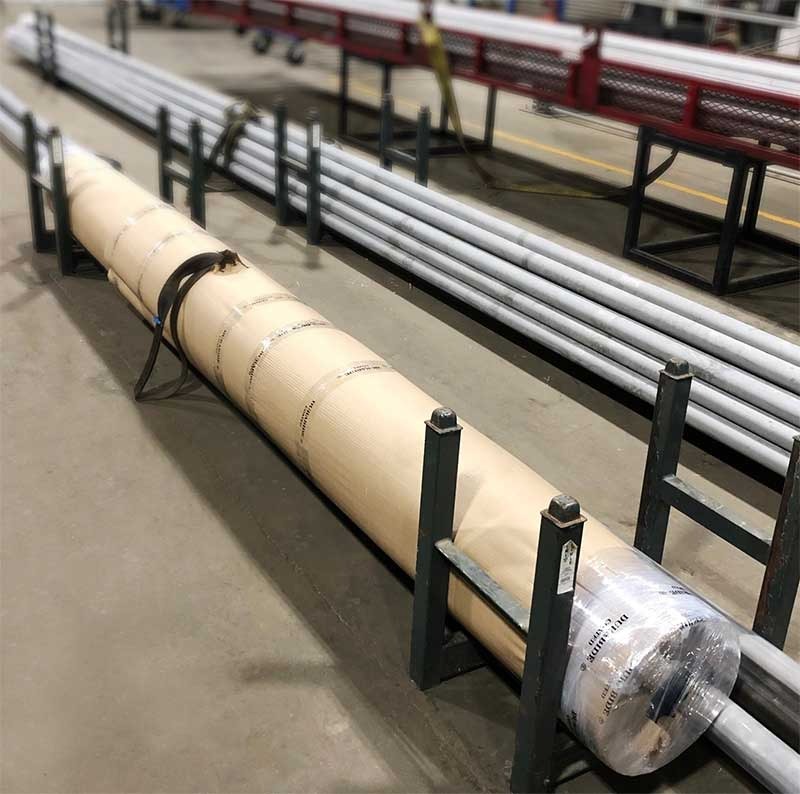

One of the greatest strengths of electroless nickel plating is its unmatched resistance to corrosion. Unlike chrome, which can develop micro-cracks in the finish, electroless nickel creates a uniform, pore-free coating that seals the surface of the metal. This makes it the preferred choice for anti corrosion metal coaters serving industries such as oil and gas, aerospace, and electronics.

The durability of electroless nickel is also superior. Its hardness rivals that of chrome, and when combined with advanced composites such as PTFE or silicon carbide, it provides exceptional wear resistance and low friction properties. This ensures that components last longer in demanding environments, reducing maintenance costs and extending the life cycle of critical parts.

Decorative Appeal Without the Hazards of Chrome

While industrial applications often focus on performance, decorative finishes remain an important part of the discussion. Home renovation products—such as faucets, cabinet handles, and sink fixtures have traditionally relied on chrome to achieve their shiny, reflective surfaces. However, electroless nickel can be polished to achieve the same brilliant, high-gloss look that consumers expect.

In fact, electroless nickel coatings offer additional advantages for decorative parts. Because the coating is applied uniformly, even on complex geometries, it avoids the inconsistencies and micro-cracks sometimes found in chrome finishes. For manufacturers producing high-end building products, electroless nickel represents a safer, more durable, and equally attractive alternative.

A Logical Choice for Manufacturers in Dallas and Beyond

Manufacturers in regions such as Texas are already recognizing the benefits of electroless nickel plating. As environmental standards become stricter, facilities offering chrome plating in Dallas, Fort Worth region for example are under increasing pressure to modernize or phase out traditional operations. At the same time, demand for safer, high-performance coatings continues to rise. For those seeking metal coaters near Dallas, it makes sense to partner with providers who specialize in electroless nickel rather than risk the liabilities associated with hexavalent chrome.

Why the Industry is Moving Away from Chrome

The shift is not simply about compliance, it’s about value. Electroless nickel reduces total lifecycle costs for manufacturers by lowering maintenance needs, extending product life, and reducing downtime caused by part failures. It also positions companies as forward-thinking, environmentally responsible organizations. When compared head-to-head, electroless nickel outperforms chrome in corrosion resistance, durability, and finish quality, all while avoiding the toxic baggage that comes with chromium chemistry.

Making the Switch: Chrome vs Nickel Plating

When evaluating chrome vs nickel plating, the conclusion is straightforward: electroless nickel offers a better, safer, and more sustainable finish for both industrial and decorative applications. From heavy-duty machine components to elegant fixtures in modern homes, nickel coatings provide the strength, durability, and appearance manufacturers need without the drawbacks of chrome.

For companies committed to future growth and responsible operations, the path forward is clear. Now is the time to transition from outdated chrome finishing to electroless nickel plating. By doing so, manufacturers can reduce risk, improve product performance, and align with evolving industry standards.

Your business deserves more than compliance—it deserves coatings that deliver safety, durability, and beauty. Replace your metal coaters that specialize in chrome plating with those who deliver advanced electroless nickel plating solutions.

Post a comment